| Equivalent grades |

GB |

DIN |

AISI |

JIS |

- |

| Cr12 |

1.2080 |

D3 |

SKD1 |

- |

| Chemical Composition |

C |

Si |

Mn |

Cr |

P |

S |

- |

- |

- |

- |

| 1.90-2.20 |

0.10-0.40

|

0.15-0.45

|

11.00-12.00 |

≤0.03 |

≤0.03 |

- |

- |

- |

- |

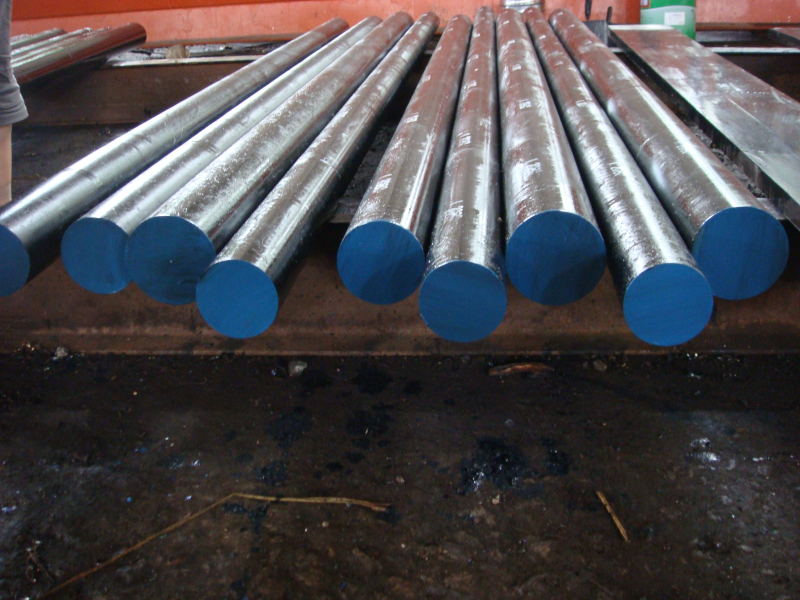

| Available size |

Round Bar |

Diameter |

Length |

| 60-800mm |

2000-6000mm |

| Flat Bar |

Thickness |

Width |

Length |

| 25-400mm |

200-800mm |

2000-6000mm |

| Surface condition |

Black surface/ Grinded/ Machined |

| Annealed hardness |

HB250MAX |

| Characteristics |

High strength, good hardenability

High abrasive resistance and small shock load

Very high wear resistance against abrasive and adhesive wear

Medium toughness

Dimensionally stable

High compressive strength |

| Applications |

High performance cutting tools for steet upto 4mm thickness,trimming dies,blanking dies for paper and plastic ,shear blades for cutting light gauge materialthreat rolling dies,drawing,deep drawing,pressure pads and highly wear-resistant plastic moulds |

| Heat Treatment |

Along with the furnace cooling after(850~870) °C× (3~4)h . (740~760)°C×(4~5)h,out air cold

Low impact toughness and should avoid tempering at about 950~1150°C |

|

|